Industry 4.0, lever to speed up the resilient supply chain

Regulatory and commercial environment in the maquiladora industry

3 September, 2020

Investment in technology, key for competing under the USMCA

3 September, 2020

Industry 4.0, lever to speed up the resilient supply chain

Today, companies must respond to volatile demand, uncertain supply and limited capacity. This volatility has highlighted the need to implement features of the digital transformation and industry 4.0, with the aim of increasing the speed of response in face of changing demands.

The new normality has demonstrated the need to build an agile and resilient supply chain that is capable of responding to increasingly demanding consumers who will look for products based on their needs with view to sustainability.

Therefore, production processes and an adequate supply chain need to be implemented to manage and mitigate disruptions and maximize business opportunities in times of uncertainty.

Industry 4.0 as the engine of an agile and resilient supply chain

Industry 4.0 started with the smart factory; however, it represents much more than that. As the cost of sensors was reduced and ecosystems matured, smart products and assets were developed that are capable of capturing more information and integrating intrinsically into horizontal business processes. This has given Industry 4.0 the potential to move from a factory-focused initiative to a company-wide business strategy.

According to Ana Núñez, director of the Center for Global Excellence in Digital Supply Chains at SAP Mexico, when a company has visible production plant availability, as well as the collaborators and operators available at each shift, it is possible to analyze the performance and quality to make product runs according to the master production plan.

In addition, you can have the visualization of operational and tactical indicators, such as OEE, levels of service and quality, availability and performance per line, together with the economic valuation allows market response times to be sped up amid volatile and uncertain times.

Worldwide, there are cases that show the positive aspects of optimizing production chains. For example, they have moved towards digital manufacturing where the automation of their plants plays a key role in responding to the volatility of demand and caring for the health of their employees by monitoring the programming and availability of production lines in real time.

Smart products and assets provide information about business processes, from design to operation. Such intelligence can empower users through integrated analytics and prescriptive capabilities, increase productivity, reduce costs, and drive entirely new business models and revenue flows.

Customization, connectivity and intelligence

Today, companies are opting for the use of customized intelligent products that can capture information or be controlled remotely on every personal device.

The supply chain requires a digitized product life cycle from design to retirement to improve and automate innovation, design, product engineering and packaging processes. Information generated by these products can therefore be shared among different engineering, manufacturing and asset management areas, providing added value in terms of agility and flexibility in the production plant.

Without a doubt, the advantage of product intelligence is its enormous flexibility to last minute changes, which can be coordinated from engineering areas to integrate them into the production and logistics process.

This generates agility in the response time and a superior advantage from the point of view of product traceability.

Therefore, companies must be able to maintain operational continuity even amid changing conditions, in order to cater to customer requirements without loses in productivity and resilience.

Automation through the IoT

Automation via the Internet of Things (IoT) can enable a digital mirror of the supply chain that provides several benefits such as:

- High levels of flexibility to meet customer demands.

- Optimizing and automating production lines to increase responsiveness.

- Significantly reduce supply chain costs by maintaining or increasing service levels.

- Increasing accuracy in warehouse, transit and production line stock levels.

- Having real-time traceability throughout the logistics network.

- Achieving a balance between profitability and availability of healthy assets.

- Increasing the security and decision-making capacity of collaborators.

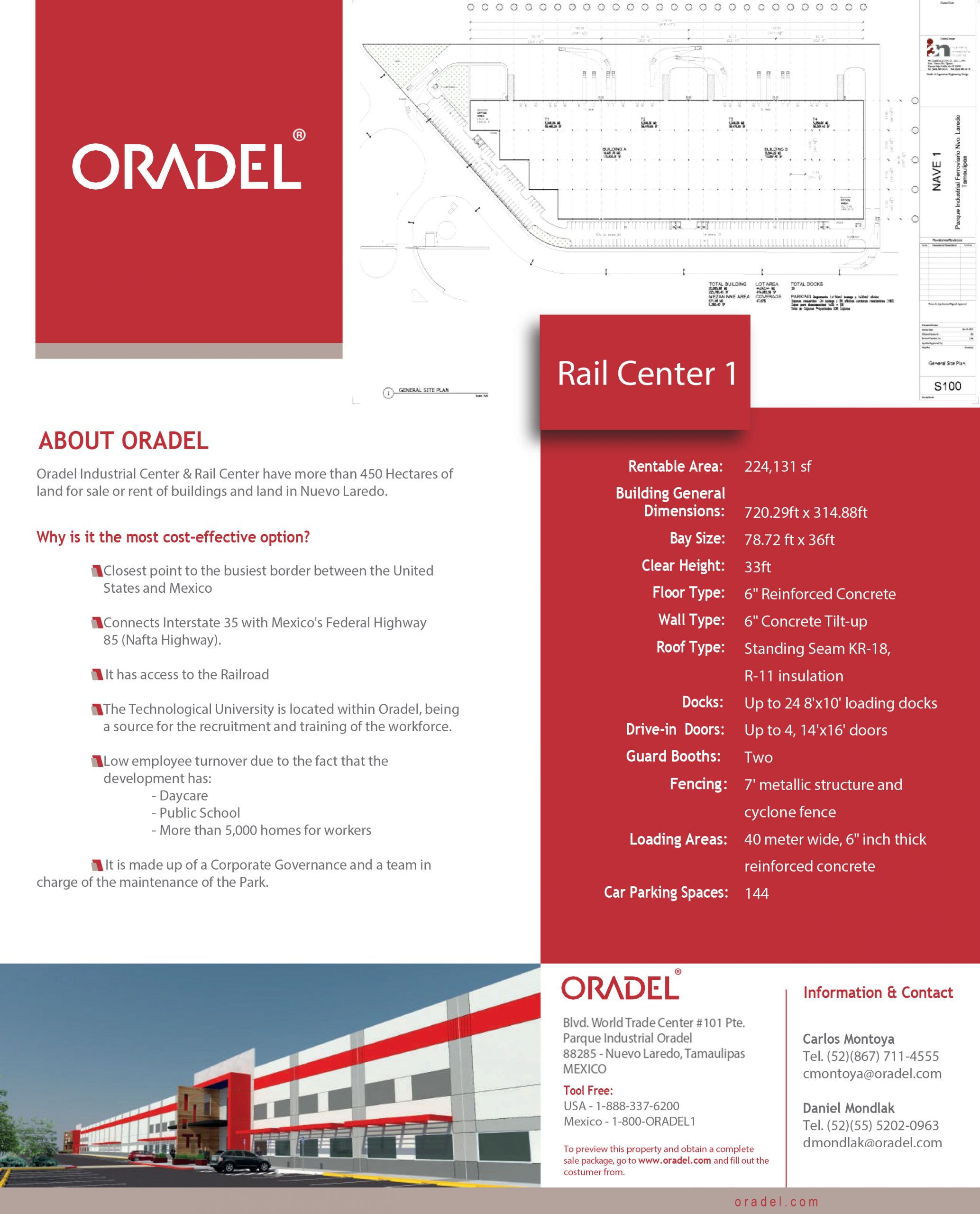

Oradel Industrial Center provides class A industrial buildings for international manufacturing companies to implement all the technology they need in their production operations.