Smart Manufacturing: driving economic growth in Mexico

The strengths of industrial real estate markets in Mexico

3 September, 2020

USMCA to drive new international production plants in Tamaulipas

3 September, 2020

Smart Manufacturing: driving economic growth in Mexico

Digitization and automation are impacting all industries; more and more companies are realizing the importance of transforming their operations with the help of technology and smart manufacturing.

In Mexico, the manufacturing industry represents approximately 25% of the Gross Domestic Product (GDP) and has historically been the driver of the country’s economic growth. Today, this sector has managed to position itself as an important global player and is expected to continue to improve through the implementation of Industry 4.0.

A new revolution

According to David Benitez, Strategic Account Manager at Motorola Solutions Mexico, for companies in the manufacturing sector, one of the most important challenges for implementing emerging technologies such as cyber-physical systems, autonomous machines and systems, the Internet of Things (IoT), intelligent manufacturing, big data, macro data analysis, cloud computing, simulation of visual environments, artificial intelligence, cyber security and augmented reality, is that the proper integration between the traditional functions of Information Technology and the functions responsible for innovation in operation through operational technologies (OT) must be planned, which can be implemented through manufacturing, storage and logistics areas.

Unlike the three previous industrial revolutions, the fourth industrial revolution allowed a large number of technologies to coexist and intermingle, resulting in a connected and interoperable ecosystem with a large volume of data and exponential growth with real-time connectivity.

Today’s smart manufacturing plants must be instantly connected and have a reach of value, enabling decisions to have a ripple effect throughout the organization and spread across the supply network. This way, Industry 4.0 or the fourth revolution has the potential to increase the productivity level of manufacturing companies by 50%.

New technology for the manufacturing industry

Today, technology allows for decentralized decision-making and the transition from preventive models to predictive models that can be applied in all areas, such as in the supply chain (adjusting times in the provision of supplies and minimizing the need for inventories), in equipment failure detection systems (eliminating preventive shutdowns and anticipating failures), and in the logistics system (anticipating the need for supplies and finished products, making distribution and delivery more efficient.

The intelligent use of resources is also a need that is reflected in cost reduction and increased productivity in companies, since through the implementation of technology, it is possible to determine what resources are needed to perform a task more efficiently by designating the closest or most suitable person for such action.

Therefore, it is important for each company to analyze and define its own goals, strengths and weaknesses before embarking on its own path of transformation. Without a doubt, in order to boost productivity and improve a company’s competitive advantage, the next step is to understand how to manipulate a large amount of data for a specific, profitable use.

According to the PwC consulting firm, the digitization process of the world’s manufacturing industry is expected to result in a cost reduction of more than 420 billion dollars by 2025, as well as an increase of 493 billion dollars in annual income. This allows us to see that a path of constant change, opportunities and challenges for the manufacturing sector that will continue, where the global adoption of technologies combined with the 4.0 trend will increasingly allow the digitization of the sector to consolidate and generate more intelligent production plants.

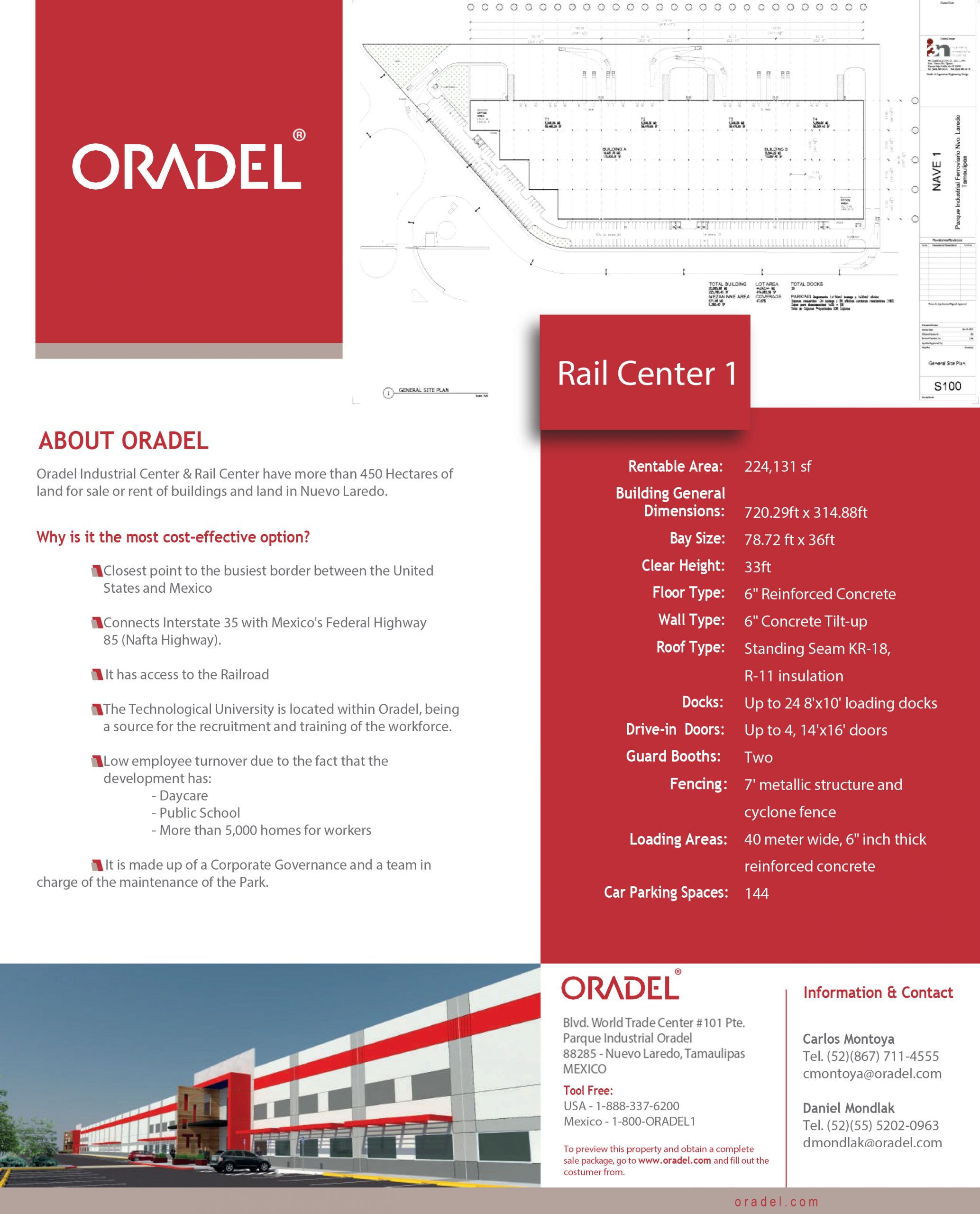

At Oradel Industrial Center, companies find space to build industrial buildings based on their needs and can use technology to make their manufacturing operations more efficient.