The importance of robotics in the supply chain

Automakers will produce in conjunction until 2025

13 July, 2020

Mexico, the new logistics hub in North America?

13 July, 2020

The importance of robotics in the supply chain

The integration of robotics in warehouses and factories around the world has been a growing trend for several years, but the coronavirus is boosting the use of collaborative robots in the supply chain like never before.

The emergency created by the COVID-19 encouraged the use of robotic solutions, especially in the medical industry. However, as manufacturers develop strategies to keep their workers safe on the factory floor, the implementation of robotics is gaining ground in different manufacturing sectors. In addition, robots can keep production safe and efficient, even in times of crisis.

Essential work during the pandemic

As governments implement aggressive actions to contain the spread of the COVID-19, major robotics companies are analyzing whether they could integrate robots into essential companies. It was their main customers who insisted that it was possible, so the implementation of automation and robots could be a cutting-edge opportunity not only in times of crisis, but also in times of prosperity.

As governments implement aggressive actions to contain the spread of the COVID-19, major robotics companies are analyzing whether they could integrate robots into essential companies. It was their main customers who insisted that it was possible, so the implementation of automation and robots could be a cutting-edge opportunity not only in times of crisis, but also in times of prosperity.

The effect of COVID-19 on the supply chain

The health crisis has led companies to examine and rethink their supply chains. In addition, the robotics industry has also had to face this change, however, it has managed to adapt to the new challenges better than other sectors.

For Jürgen von Hollen, President of Universal Robots, the crisis meant moving away from supply chain rigidity, so steps were taken to discover how to be practical.

Robots and sanitation

COVID-19 is a virus that can remain active for several days, depending on the surface material. Therefore, maintaining maximum cleanliness has been key to reducing the possibility of infection, and in this area the use of robotics has been essential. During the critical weeks of the pandemic, solutions for disinfecting work spaces were key. In fact, the disinfection abilities of robots have generated a lot interest in companies looking to maintain operations.

Operating remotely has been a challenge for most companies, however, those with digital processes and cloud capabilities have been able to cope more effectively with the emergency.

The post-COVID-19 scenario

The disruption caused by coronavirus has modified the way companies operate, and some of these changes could remain after the emergency. Unlike other crises, such as the 2008 recession, the pandemic is actually changing the way business is done.

The new normal will also generate a significant increase in the demand for products, as well as a challenge for companies recruiting talent, as they will have to keep their teams committed and focused.

However, it is clear that flexibility will be the new norm, and adapting to new ways of working will contribute to the survival of businesses. However, ensuring safety will be key once employees are able to return to their workplaces.

The future of factories in Mexico

Following the pandemic, it is likely that there will be a resurgence of product manufacturing in North America, including Mexico, rather than the traditional trade between the United States and China.

The volatility of tariffs in 2018 and 2019 exposed the risks of having China-dependent supply chains; however, this did not make manufacturers move their operations to the United States, but rather to diversify their trade away from China by establishing themselves in other countries in Southeast Asia, such as Vietnam, Thailand and Cambodia, which represent a lower-cost alternative.

The initial clustering of the pandemic in China seemed to accelerate the trend described above, but it became clear that no country is safe from the consequences of COVID-19. Companies had to keep some factories open and suddenly close others, facing the logistical challenge that this entails.

In addition, some companies have indicated that they have problems with factory closures or staff shortages in Mexico, and although local governments are allowing the gradual reopening of businesses, the standards differ from the standards that United States is taking into account for this situation.

In view of the above, one solution is to build more factories in more countries, including the United States, to avoid the destabilization of supply chains.

Also, with regard to automation, companies are currently looking for ways to attract more people to their factories. However, rising wages in Asia and tariffs between the United States and China have decreased the economic attractiveness of the Asia’s manufacturing industry, especially if companies can replace employees with machinery, and thereby reduce costs.

There are currently U.S. companies that earn approximately half of their revenue in Mexico, and the remaining amount in the United States, yet Mexico is unlikely to benefit from more centralized manufacturing.

The fact that a possible trade war between the United States and China coincided with the restructuring of the North American Free Trade Agreement slowed foreign direct investment in Mexico, as companies were reluctant to make new investments before they knew the new trade regulations.

With tariffs still in place on imports from China, there is an interest in having plants near the final market, and the market considers Mexico a great place to do business.

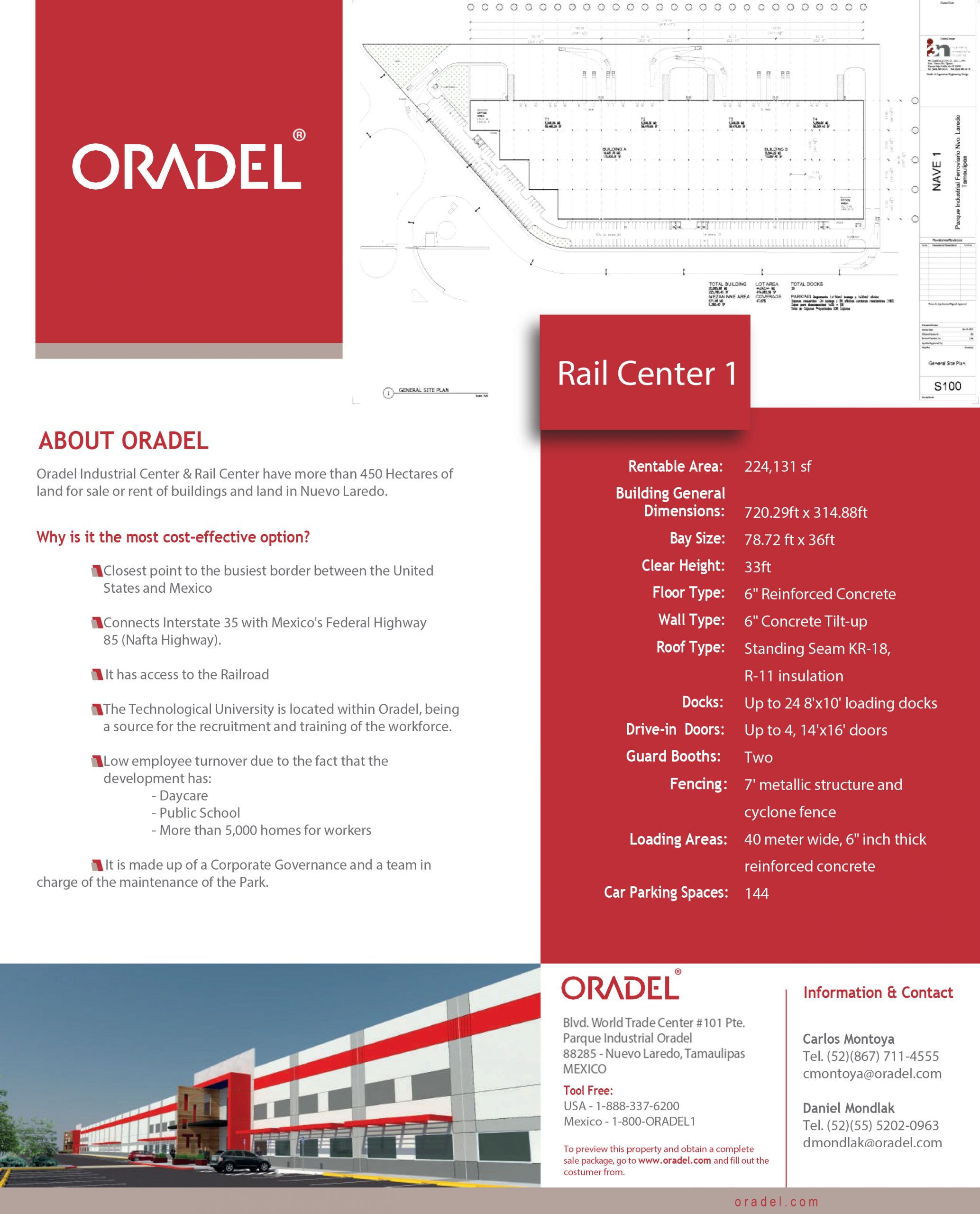

For all these reasons, Oradel Industrial Center, an industrial park located in Nuevo Laredo, Tamaulipas, offers international companies the opportunity to establish manufacturing operations right next to the border with the United States.