Digital transformation and automation, solution for companies against coronavirus

T-MEC and TLCUEM, keys to reposition Mexico after Covid-19

26 June, 2020

Supply chain changes through 3D printing

13 July, 2020

Digital transformation and automation, solution for companies facing the coronavirus

The mobility restrictions to avoid Covid-19 infections are an opportunity for companies to advance in the area of digital transformation and automation of their production processes.

In this context, companies see the opportunity to take advantage of the fourth industrial revolution, also known as Industry 4.0, to continue their digital transformation by adopting different solutions.

According to Alejandro Preinfalk, Director of Digital Industries of Siemens Mexico and Central America, digitization generates improvements in delivery times, reduces operating costs, energy and optimization of production processes that represent a 30% increase in productivity and profitability. These aspects will be important once activities are restarted, after the closure of the economy due to the pandemic.

In addition, the executive stressed that the adoption of Industry 4.0 can help improve the productivity of the industrial sector and boost the recovery of the economy, elements that are key today due to the effects that the Covid-19 pandemic leaves on the plant global and local production.

Given the current global situation, companies have implemented remote services to support their clients to solve machinery problems remotely, as well as advice on the appropriate technology to enhance productivity.

Industry 4.0: Rising to the Challenge

In recent days, Siemens Financial Services (SFS) published new research titled Industry 4.0: Rising to the Challenge, where it unveils the investment challenges facing manufacturers to migrate their businesses to new technologies. This research estimates that the global investment for digital transformation in the industry is almost 400 billion dollars in the next five years.

Today, with economic uncertainty, investing in digital transformation is the difference for businesses between surviving and thriving. So Siemens has generated a model that conservatively estimates the magnitude of investment development facing the manufacturing industry and the implementation of technology for digital factories during the period 2020-2024.

This is because in previous SFS investigations it was revealed that the turning point for investment will be in a period of 5 to 7 years, in which half of manufacturers will have migrated substantially to the production platforms of Industry 4.0 .

Industry 4.0 benefits

According to Siemens, some of the benefits of Industry 4.0 are the reduction of the costs of the production processes and the increase in income by an average of 6%. In addition, the digitization of factories will allow global implementation of predictive maintenance techniques that will reduce costs by 12% for the industrial sector, plus inventory maintenance that will reduce costs by around 20 to 30% worldwide.

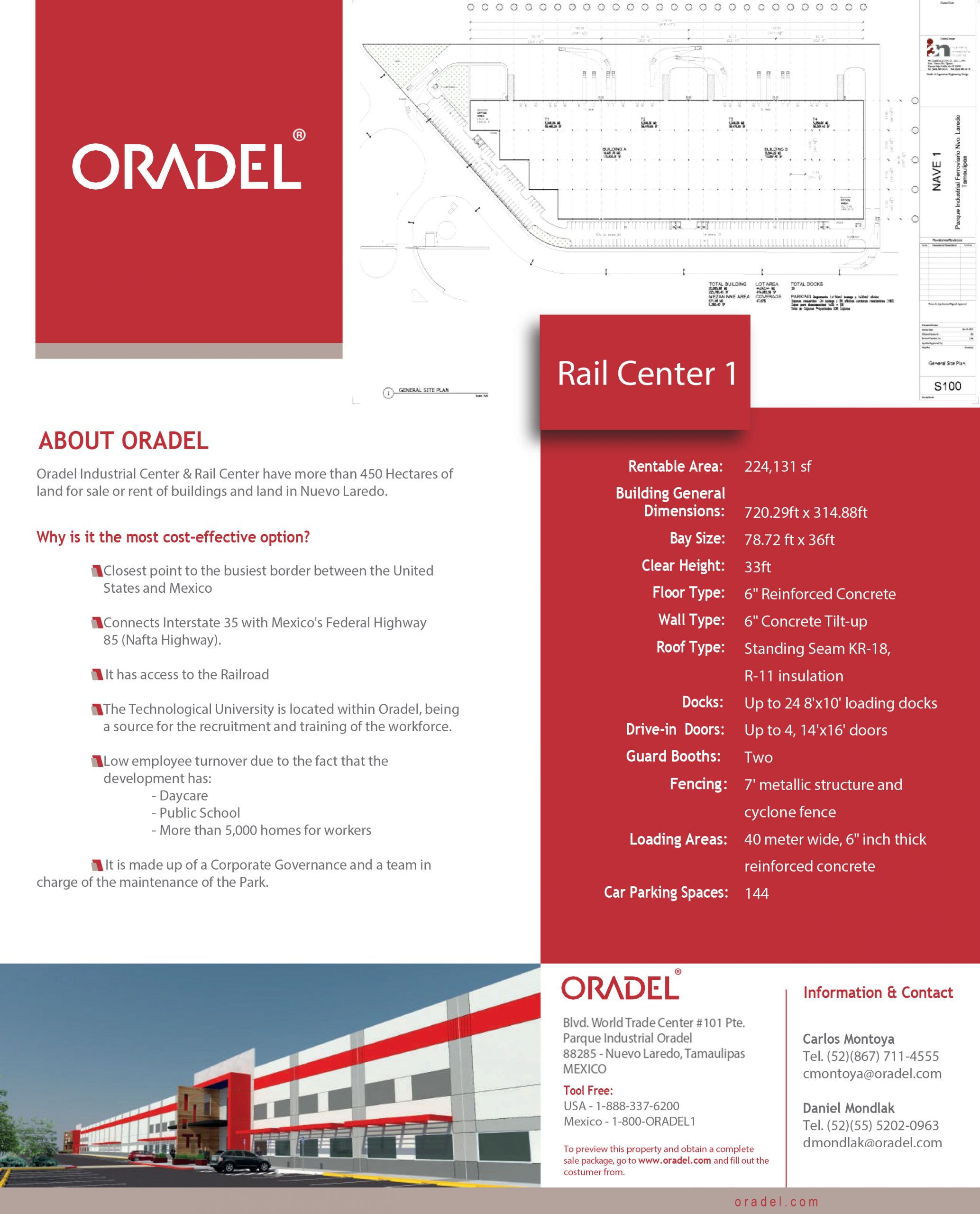

Oradel before Industry 4.0

For 20 years, Oradel Industrial Center has sought to offer various alternatives to international companies seeking to establish their manufacturing operations in Mexico. One of the advantages of this park is the construction of industrial warehouses as companies’ “suits to measure” (Build To Suit), with which the digitization of manufacturing operating processes can be implemented.