The maquiladora export industry will replace 20% of Chinese inputs with local products

The manufacturing industry would have grown by almost 8% by the year’s end

11 November, 2020

Foreign Direct Investment, an opportunity and a challenge for Mexico

11 November, 2020

The maquiladora export industry will replace 20% of Chinese inputs with local products

Mexico’s maquiladora export industry will replace 20% of Chinese inputs with local products this year due to the impact of the coronavirus pandemic.

According to Bernardo Fernández, Director of the Center for Electrical Research, this replacement of imported inputs from China by national suppliers can create more competition in the prices of local raw materials, since one of the objectives is to add value to those produced in Mexico and improve their prices, to make them more competitive in the international market.

This year, the aforementioned trend may grow up to 20% due to the disruptions in the production chains and international trade caused by COVID-19 and by the depreciation of the Mexican peso.

According to data from the National Council of the Maquiladora and Export Manufacturing Industry (Index), over the last five years, Mexican maquiladoras have replaced 12.5 billion dollars’ worth of Chinese inputs, giving an annual average of 2.6 billion dollars.

Furthermore, Bernardo Fernández notes that at the beginning of the COVID-19 pandemic, the price of freight transport doubled. In addition, the production plants in China canceled order deliveries because they had stopped production.

Imports have already resumed; however, many Mexican companies are supporting small maquiladoras and local suppliers to improve their technology and products so that they may supply the market.

This trend can be seen in sectors such as plastic components, which were previously only available from China and are now produced in Mexico at a high quality and with the appropriate requirements for domestic demand.

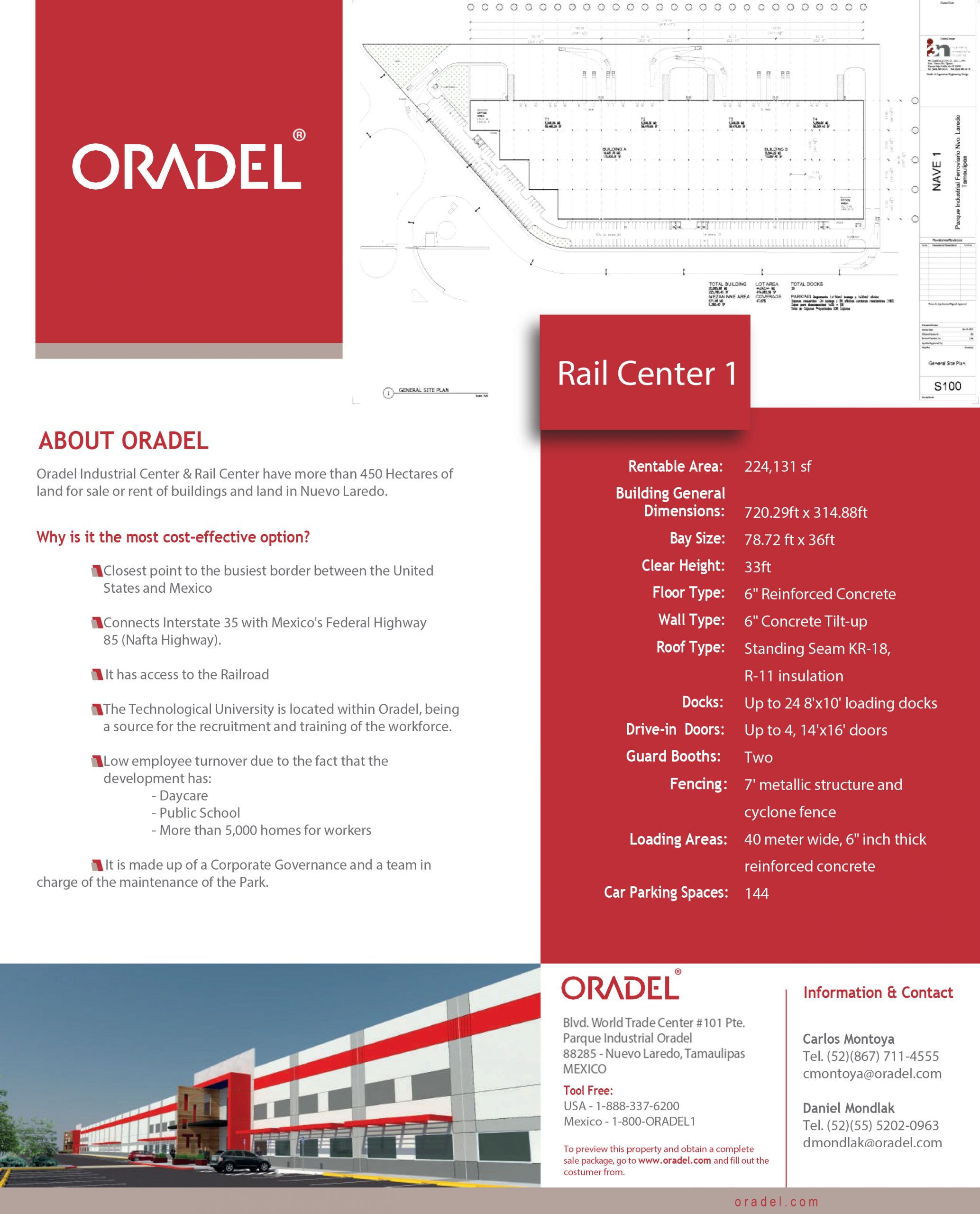

Oradel Industrial Center has the best location in the US-Mexico border for the maquiladora export industry. It offers industrial buildings for immediate occupancy with all the infrastructure (gas, electricity, roads, rail service etc.) in place. It also offers “built to suit” buildings designed specifically for the industry’s needs.