Industrial parks require advanced technology for better efficiency

New perspectives on the future of the automotive industry

18 December, 2020

Manufacturing industry expected to close 2020 without any impact

18 December, 2020

Industrial parks require advanced technology for better efficiency

Given the growth of the industrial sector in Mexico and the rise of new technologies worldwide, industrial developers must opt for intelligent industrial parks based on Industry 4.0 technologies for the efficient use of their resources.

According to a study conducted by CREA, a consulting group specialized in real estate projects and market studies, since 2018, industrial parks in Mexico have registered a considerable increase in construction projects, expansions and operations, with 512 parks built and 51,768 hectares available.

This growth scenario, together with the current crisis situation due to the COVID-19 pandemic, has created the need for a strategic shift based on Industry 4.0 by industrial park developers, due to competition issues and labor costs involved in technologies such as the Internet of Things (IT), artificial intelligence (AI), big data and virtual reality (VR), which allows for optimal product control, more efficient processes, increased productivity, quality, safety and quality of life of operational staff.

According to Logicubus, a digital solutions and automation company based in Latin America and the United States, Industry 4.0 is characterized by working with the digitization of industrial processes and resource optimization focused on intelligent infrastructures. In addition, this optimization has the ability to respond to the difficulties related to operation and safety in the workplace in the context of the pandemic in areas such as staff management, vehicles and goods, with the aim of improving both safety and operational efficiency.

Of course, each industry sector faces unique challenges, so solutions must be tailored to specific needs and deliver value to improve operational efficiency and optimize workflow.

In addition, the use of digital tools and advanced technologies in designing intelligent solutions applied to industrial parks encourages innovation and experimentation within the sector.

Industry 4.0 as a necessity

Representatives from CONCAMIN, Hannover Fairs Mexico and UNIDO agree that if Mexico expedites the incorporation of automation, as well as conducting studies aimed at digital growth, there is a possibility of raising GDP growth by an additional 3 percentage points.

Currently more than 90% of the productive activities in Mexico do not use technology. This is why it is important for the government to develop a long-term industrial policy.

According to José Luis de la Cruz, President of CONCAMIN’s Economic Studies Commission, the COVID-19 pandemic caused an international financial shock leading global economies to fall into economic recession, thus requiring a strategy involving new technologies and automated production systems that raise productivity. In addition, Mexico slowed down the pace of the Industrial Revolution 4.0 because it lacked an industrial policy, an innovation and technology budget, as well as the connection between education and business.

For CONCAMIN it is important that the educational system has curricula aimed at digital development, which would result in raising GDP growth by 3 percentage points, adding to the 2 average points recorded by the economy and reach a total of 5 percentage points. With this result, 35 billion dollars could be generated annually, and 600,000 additional employees could be hired.

According to Bernd Rohde, CEO of Hannover Fairs México, the country is a manufacturing nation, and its economic value is not one of the best, so it has to integrate digital manufacturing in all its industrial processes.

In addition, Guillermo Gonzalo Castellá, Director and Representative of UNIDO’s Regional Office in Mexico, said that Industry 4.0 has increased the need for an industrial policy with a comprehensive and long-term vision, based on strengthening the productive linkages of strategic sectors and increasing domestic content to facilitate market diversification and boost competitiveness. Therefore, Mexico requires more innovation and technologies in industrial parks to address the lags generated by the pandemic.

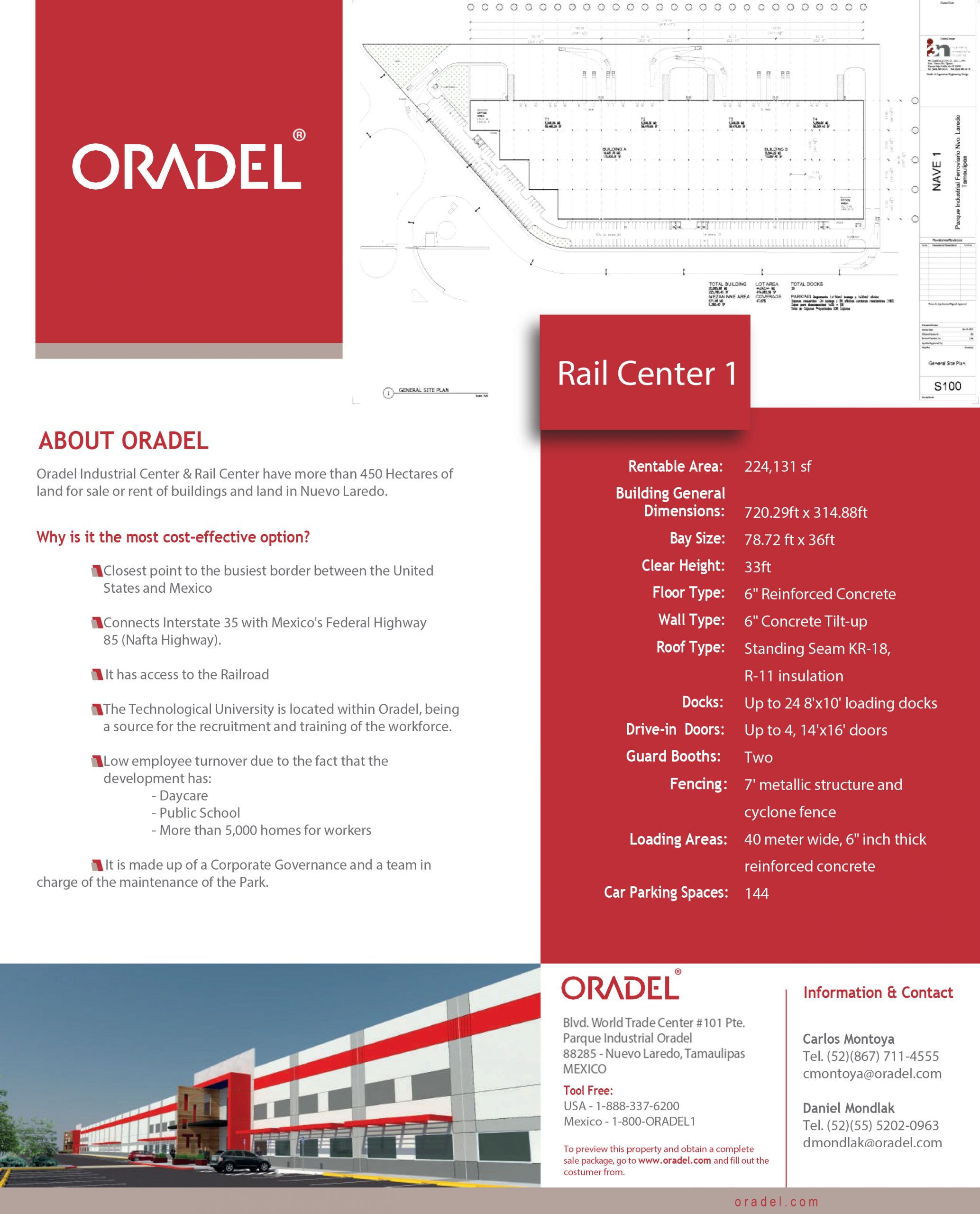

Oradel Industrial Center offers the possibility of implementing technologies in the production processes of companies that are within the industrial park. The Park offers all the infrastructure necessary for the establishment of manufacturing and logistics industries.